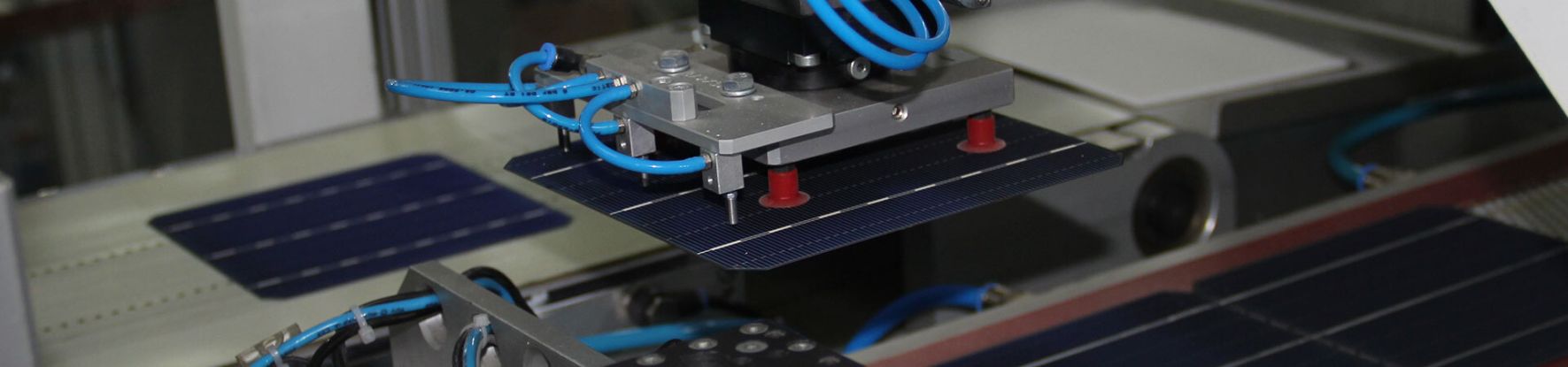

Sorting and Screening Solar Panel Crystalline Cells Using Crystalline Cell Testers

Solar Panel Manufacturing

Home

PRODUCTION

The steps required to run the streamline are

Competitive advantage

LA Solar uses only premium materials and equipment. Every product undergoes internationally recognized quality certification testing. We constantly update our machinery with the latest innovative technologies and train our technical personnel to control and maintain it. LA Solar solar modules correspond to all eco-friendly regulations.

Our products have three crucial certifications that cover all the safety, health, and environmental requirements (ISO45001, ISO14001, ISO9001).

LA Solar products fully comply with standards for renewable energy sources. All our modules come with a long-term warranty. The conventional capacity of solar modules is not less than 90% for 12 years and not less than 80% for 25 years. LA Solar is your partner for a long-term journey to the clean and green world of trust, and support.

Get our PV modules at more competitive prices compared to those in Europe and the USA.

Through its high production capacity, LA Solar can offer an unlimited supply to its clients and extremely attractive deals to its partners.